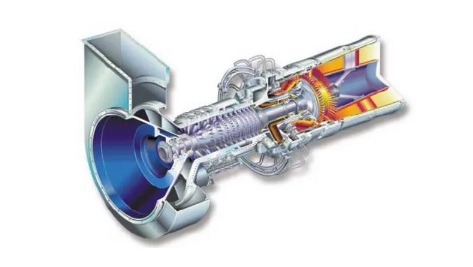

The GE5 is a compact, state-of-the-art, 6 MW class industrial gas turbine. It has two configuration in use; a cold-end drive single shaft for power generation and a hot-end drive twin shaft for mechanical drive applications. Both configuration share a share a common gas generator, with operating and maintenance benefits in installations where mixed operation is required.

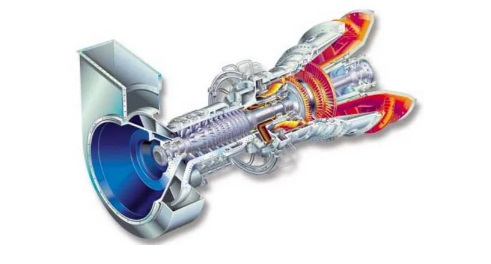

In twin shaft engine, the second stage turbines from single shaft unit is removed and added a two stage power turbine.

Image of GE5 single shaft gas turbine

The single shaft version is particularly suitable for power generation and cogeneration due to the high exhaust temperature, the twin shaft version, with wide operating speed range, is designed to be a reliable and efficient mechanical drive for compressors and pumps.

Image of GE5 Twin Shaft gas turbine

This engine has high efficiency and reliability, and low operating and maintenance cost. The high efficiency of the machine coupled with low emissions make the GE5 a leader in its class for most applications.

Main Sections: The Compressor:

The GE5 compressor is scaled from the GE10 unit, and the benefits from several decades of compressor design evolution focused on achieving higher efficiency. It is a high performance, axial flow design derived from GE Aircraft Engine technology. The 11-stage compressor produces a pressure ratio of 14 8:1. The first three stages of stator blades are adjustable to optimize efficiency by maximizing exhaust gas temperature at part load operation.

Main Sections: The Turbine:

The HP turbine itself is a compact, high efficiency design with two stages in the single shaft version and three stages in the twin shaft model (2 in the LPT Turbine). The GE5 uses an enhanced nozzle and bucket design similar to those used in aircraft engines. Cooling air is provided to the first stage nozzles and buckets to enable higher firing temperatures and enhanced

efficiency.

The LP turbine of the twin shaft version has two stages and has been designed exploiting the experience the company has gained over the past 20 years with the PGT25, PGT10, PGT16 and more recently with the GT25+ (High Speed Power Turbine). The design speed of the GE5-2 low pressure turbine is 12,500 rpm, with a capability range from 50% to 105%, which is ideal for

direct coupling of GE Energy centrifugal compressors in the 6 MW power range.

Main Sections: The Combustor:

The GE5 uses an annular combustor architecture, to achieve the maximum efficiency while maintaining the highest reliability standards. The unit is configured with a DLE combustion system that reduces the NOx and CO emission levels. It consists of a compact annular combustor in Hastelloy X with 18 fuel nozzles. Each fuel nozzle includes a double counter-rotating swirler to

optimize fuel mixing and flame stability for extra clean combustion. This combustion system is designed for operation on

natural gas. One fixed, high-energy spark ignitor is used to achieve simple and reliable ignition.

Key Factors:

- Annual borescope inspections are the basis of the condition based maintenance program.

- The inspection of the hot parts is carried out approximately every two years.

- Major overhaul of the gas turbine is required at around 50,000 fired hours,